Sustainably excellent hall and office air conditioning from a single source

Tradition and precision define mechanical engineering specialist ANG, based in Luxembourg. In its new building, the company decided for a Hoval air conditioning solution that delivered precision – and sustainability to go along with it.

- Production Hall

- New Building

- Indoor Climate System

A new building with special requirements

In 2023, ANG established a new building in an area of green space. © Vincent Piront S.A.

Simple, reliable and economical: a winning solution from a single source

The Belaria fit (53) heat pump is used to provide heating and cooling for the site through underfloor heating and cooling ceilings.

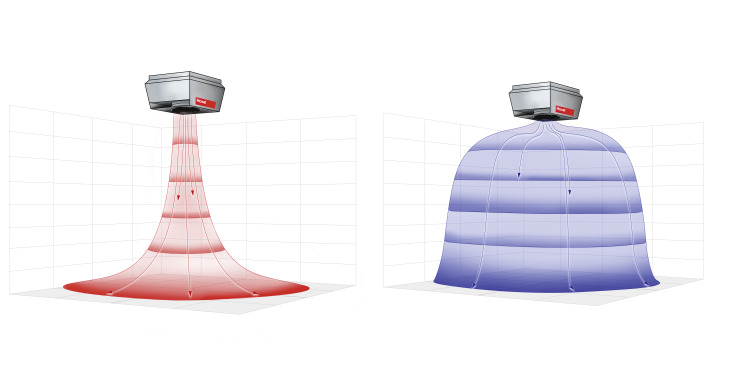

In both heating and cooling mode, the Air-Injector automatically ensures optimum air distribution with minimum air velocity.

Our customer loved the proposal: it was ecological, cost-effective and easy to install.